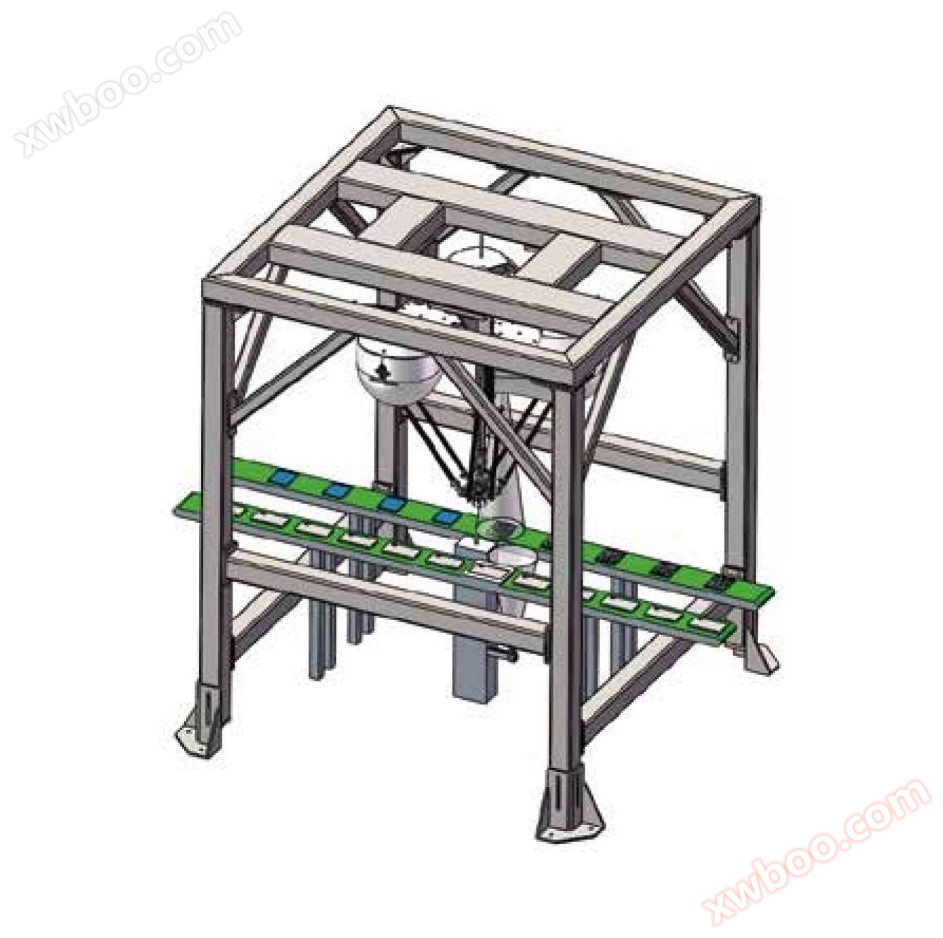

In the case, the incoming material on the conveyor belt is equipped with 50 A patch material box. First, send it to the camera 1 At this point, pose recognition is performed, and the Burkent direct drive robot adjusts the angle based on the information to accurately grasp the patch movement and apply glue to the glue outlet. Then, the camera is used 2 Perform secondary recognition of the outer contour of the patch, communicate pose information to the robot, control its rotation to the position to be pasted with the phone, and perform precise pasting. If the camera 1 When the identification box is empty, the customer will be reminded to change the material.

Throughout the entire process, the robot's accuracy reached0.01mmStrictly ensuring the final process accuracy, achieving efficiency while also reducing the on-site footprint of the equipment.

| Results after implementation | data |

| Reduce manpower | 0 people |

| Efficiency growth | 33% |

| takt time | 60 pieces/minute |

| defective rate | 0 |

| floor area | 9㎡ |

| Payback Period | 2 years |

This application is used in3Celectronic、daily necessities、Food and beverage, stationeryIt has been widely used in multiple industries.Nanjing Ruiyi Intelligent Technology Co., Ltd. can customize according to customer needs.

| Nanjing Ruiyi Intelligent Technology Co., Ltd |

| Address: No. 28 Fengshou Road, Dongshan Industrial Concentration Zone, Jiangning, Nanjing |

| Telephone: |

| Fax |

| For business cooperation, please contact | |||

|

Scan and add WeChat

|

||